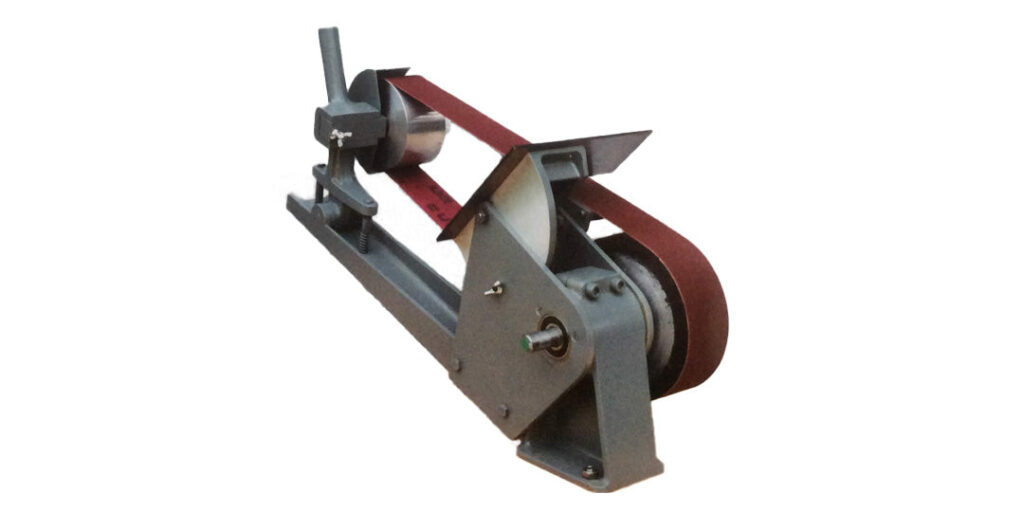

The WEN 6502T 4 x 36 in. Belt and 6 in.

Disc Sander stands out as the best belt sander for knife making. Its versatility and reliability make it a favorite among knife makers. Choosing the best belt sander for knife making involves balancing power, precision, and durability. A quality belt sander is essential for knife making, as it shapes and sharpens the blade to perfection.

The WEN 6502T excels in providing a robust construction and a powerful motor, ensuring consistency in your grinding tasks. It also features a sturdy cast iron base to prevent heavy vibrations during operation, which is crucial for achieving smooth finishes on your knives. The adjustable belt tilts anywhere from 0 to 90 degrees to accommodate the needs of different knife designs. Its ease of use and efficiency in material removal rank it highly among professionals and hobbyists seeking top-tier equipment for their craft.

Introduction To Knife Making And Belt Sanders

Embarking on the journey of knife making is an endeavor where precision meets artistry. At the heart of this age-old craft lies a tool known for its robustness and versatility – the belt sander. Essential for shaping and sharpening, a best belt sander for knife making stands as the linchpin in transforming raw materials to a finely crafted blade. Whether you’re a seasoned blacksmith or a passionate hobbyist, understanding the interplay between knife making and belt sanders is pivotal for crafting cutting-edge masterpieces.

Understanding Knife Making As A Craft

Knife making is an intricate craft that involves a series of detailed steps; from selecting the right materials to the final sharpening, each stage requires precision and skill. Patterns, forging, heat treating, and finishing all play critical roles in creating a knife that is not only aesthetically pleasing but also functionally sound. This craft is not just about producing an everyday tool, it’s a form of expression and a testament to the maker’s craftsmanship.

The Role Of Belt Sanders In Knife Making

The belt sander emerges as an indispensable tool in the knife maker’s arsenal. Specifically designed for metalworking and grinding, these machines provide the power and finesse required to shape the blade to its perfect contour. With a variety of grits and belt sizes, sanders offer unmatched flexibility to work with different materials and designs. Notably, belt sanders are responsible for tasks such as beveling, sharpening edges, and smoothing surfaces, ultimately defining the sharpness and durability of the knife.

Key Features Of Belt Sanders For Knife Making

Embarking on the journey of knife making requires precision tools, and a belt sander stands out as a crucial component in this craft. The right belt sander transforms raw material into a finely crafted blade, all while offering efficiency and ease in the process. Discerning the key features of belt sanders is essential for both aspiring and experienced knife makers. The following are pivotal elements to consider when selecting a belt sander that aligns with one’s knife crafting ambitions.

Belt Size And Material

Belt size significantly impacts the sander’s suitability for knife making. A common size that balances the ability to handle various tasks is a 2″ x 72″ belt. The width allows for sufficient surface area to work the blade, while the length provides longevity and a cooler grinding experience, which is vital to preserve the metal’s temper. Moreover, the material of the belt influences the quality of sanding. Some materials offer finer grits for a polished finish, while others can remove material rapidly for shaping the knife’s edge.

Motor Power And Speed Control

The motor’s power is a critical component of a belt sander. High-quality sanders typically feature a motor rated around 1HP (Horsepower) or higher to maintain consistent rotational force under the resistance of metal shaping. Speed control adds a layer of versatility, with variable speed options facilitating different stages of knife making, from shaping to finishing touches.

Durability And Build Quality

Durability derives from a belt sander’s construction. Tools used in knife making endure substantial stress and heat; thus, a robust belt sander fabricated from high-grade materials such as steel is essential. The build quality determines the longevity and reliability of the sander over countless projects, making it an investment in efficiency and artistry.

Versatility And Adjustability

Knife making is an art that requires adaptability. Thus, the best belt sanders feature multiple attachments and work rests for different knife designs and sizes. Adjustability in the tool’s parts, such as the belt arm, platen, and worktable, allows for an array of grinding angles and positions, enhancing precision and control.

Ease Of Belt Changing And Maintenance

During the knife making process, the belt will need to be changed to accommodate different stages of sanding. Belt sanders designed with user-friendly mechanisms for quick and effortless belt changes can significantly enhance productivity. Likewise, easy maintenance contributes to the sander’s longevity, ensuring that the belt sander remains a reliable asset in the knife maker’s toolkit.

Top Belt Sanders For Knife Making

The quest for the perfect knife hinges on precision craftsmanship—and the right belt sander is a pivotal tool in achieving that. Whether you’re a professional knifemaker or a hobbyist, the belt sander you choose can be the difference between an average blade and a stunning one. In this section, we’ll dive into the top belt sanders that have become the go-to equipment for knife making, each with unique features designed to meet various needs and preferences.

Professional-grade Belt Sanders

Professionals demand excellence, and these belt sanders deliver just that. Best-in-class power, outstanding durability, and precise control characterize these machines:

- The Wilmont LB-1000: A powerhouse with variable speed control for meticulous work.

- KMG-TX: Boasts extreme adjustability and versatility, preferred by many top-tier knifemakers.

- Burr King 760: Renowned for its robust construction and exceptional belt tracking.

Best Value Belt Sanders For Hobbyists

When passion meets affordability, hobbyists find these belt sanders to be the optimal choice:

- Grizzly Industrial G1015: An excellent blend of performance and price, ideal for beginners.

- Rikon 50-151: Compact in size yet impressive in function—your budget-friendly companion.

- Central Machinery 1 x 30: Provides adequate power for smaller projects without breaking the bank.

Compact And Portable Sanders For Small Workshops

Space constraints should never constrain quality. These compact and portable belt sanders prove that small can still be mighty:

- Porter-Cable PCB420SA: Space-saving design with no compromise on power.

- WEN 6502T: Versatile and mobile, this sander can be easily moved around the workshop.

- Work Sharp WSKTS-KO: Not just portable but also offers precision sharpening for those fine edges.

Innovative Features In New Models

The latest belt sanders come with innovative features setting new standards in knife making:

- Variable Speed Control: Allowing for a wide range of speeds to tackle diverse materials with precision.

- Adjustable Work Rests: Offer improved stability and support for consistent angling.

- Dust Collection Systems: Enhanced environmental control, keeping your workspace cleaner and safer.

Considerations For Choosing The Right Belt Sander

Embarking on knife-making ventures requires precise tools, and a belt sander stands out as essential equipment. The choice of belt sander can significantly impact the quality of your knives and the efficiency of your work. Various factors come into play when deciding on the optimal sander for this meticulous craft. Understanding your specific needs, aligning those with your skill level, considering the cost-to-performance ratio, ensuring robust safety features, and verifying the warranty and support offered are all crucial when selecting a reliable belt sander for knife making.

Assessing Your Knife Making Needs And Skill Level

Proficiency and purpose direct the choice of a belt sander. Beginners may prefer straightforward, user-friendly models, while veterans could opt for advanced machines with specialized capabilities. The frequency of use, the types of knives to be crafted, and the desired precision all play a role in this assessment.

Evaluating Price To Performance

A belt sander’s value for money is another pivotal consideration. While budget-friendly models are tempting, they should not compromise on efficacy. It is essential to balance cost with features such as motor power, speed variability, and durability. An investment in a higher-end model might be justified if it enhances your knife-making process and lasts longer.

Safety Features And User Protection

Knife making is an activity where user safety cannot be overstated. Belt sanders should have reliable safety mechanisms in place, such as emergency stop features, spark and dust arrestors, and robust machine stability to prevent accidents.

Warranty And Manufacturer Support

A solid warranty and responsive customer support can amplify the value of your belt sander. It’s indicative of the manufacturer’s confidence in their product and ensures that assistance is at hand should you encounter any issues.

Using Your Belt Sander Effectively

Embarking on knife-making projects requires precision and efficiency, and the right belt sander is your partner in crafting fine edges and smooth surfaces. But, it’s not just about having the best tool; it’s about mastering its use. Every knife enthusiast or professional understands that effective utilization of a belt sander can dramatically impact the outcome. Let’s dive into how to maximize your belt sander’s capabilities, ensuring that each knife you make showcases your skill and meticulousness.

Before starting your grind, it is crucial to establish a safe and accurate belt sander setup. Adhering to safety precautions not only ensures your wellbeing but also affects the quality of your work.

- Eye protection: Always wear safety goggles to shield against flying debris.

- Respiratory safety: A dust mask or respirator is essential to prevent inhalation of fine particles.

- Stable workbench: Secure your belt sander on a flat, stable surface to prevent unwanted movement.

- Proper belt alignment: Align the belt correctly to avoid uneven wear or potential hazards.

Test your setup to ensure everything functions as intended before you begin working on your project. Correct setup contributes to both the safety and the precision of knife making.

Achieving the perfect edge on a knife is an art that combines skill with the right technique. Understand these practices for grinding that elevate your knife making:

- Even pressure: Apply consistent pressure during grinding to avoid gouges and ensure uniformity.

- Angle consistency: Maintain a steady angle relative to the belt to achieve the desired bevel.

- Cooling intervals: Let your knife cool periodically to preserve its temper, using either a dip in water or air cooling.

Remember, practice with different grits progressing from coarse to fine, enhances the smoothness and sharpness of your knife’s edge.

Like any well-oiled machine, your belt sander demands regular maintenance to perform its best. Here are some maintenance tips:

- Clean regularly: Remove dust and debris accumulation to prevent mechanical issues.

- Check belt wear: Inspect belts for wear and tear and replace when necessary to ensure consistent performance.

- Lubricate moving parts: This reduces friction and wear and extends the life of your belt sander.

Record your maintenance schedule to stay on top of necessary tasks, and always disconnect your belt sander from power before performing any maintenance.

Even the most seasoned craftsmen encounter issues with their tools. Recognize these common hurdles and how to surmount them:

- Belt slipping or tracking poorly: Adjust the tracking mechanism and check for correct belt tension.

- Inconsistent grinding: Inspect the work rest for stability and flatness; it should be perpendicular to the belt.

- Overheating: Ensure adequate airflow around the motor and take regular breaks to prevent the sander from overheating.

Invest time in understanding your belt sander’s manual for specific troubleshooting guides related to your model. Quick identification and resolution of issues will guarantee continuous productivity and craftsmanship.

Conclusion And Final Recommendations

Delving into the art of knife making, the importance of a reliable belt sander cannot be overstated. As we wrap up the discussion, it’s essential to examine the sander features that can make or break your knife making experience and reveal our top recommendations tailored to various skill levels. No matter where you are on your knife-making journey, investing in the right tools is a step you’ll never regret.

Summing Up Belt Sander Features

A belt sander’s prowess is defined by a combination of power, speed, stability, and belt size. Power determines the speed at which you can work and the hardness of the materials you can handle, while variable speed control allows for precision during the knife shaping process. Furthermore, a stable machine reduces vibration, enhancing accuracy and safety. Always look for belt sanders with adjustable belt sizes to switch between intricate and broad-scale work with ease.

Top Picks For Different Knife Making Levels

For the budding hobbyist, a model like the WEN 6515T offers an excellent starting point with its dual belt capability and reasonable pricing. Those with mid-level expertise might lean towards the RIKON Power Tools 50-151 for a blend of power and versatility without breaking the bank. Lastly, for the experienced artisan demanding uncompromised quality and features, the Jet Tools J-4002 serves as the pinnacle of belt sanders, ensuring durability and top-tier performance for intricate knife making projects.

Encouragement To Invest In Quality Tools

Compromising on the quality of your belt sander can be a false economy, leading to subpar results and increased frustration. High-quality tools not only last longer, but they also provide the consistency and precision necessary for superior craftsmanship. Aim to invest upfront in excellence—it pays off in the long run, supporting your growth in the art of knife making and guaranteeing satisfaction with every creation.

Credit: www.redlabelabrasives.com

Frequently Asked Questions On Best Belt Sander For Knife Making

What Size Belt Sander Is Best For Making Knives?

A 1×30 or 2×72 inch belt sander is ideal for knife making, offering precision and versatility for various shaping tasks.

Can You Make Knives With A Belt Sander?

Yes, you can create knives using a belt sander to shape the blade and refine its edges. This tool is often employed by knife makers for precision grinding.

What Is The Best Grit For Sharpening Knives With A Belt Sander?

The ideal grit for sharpening knives on a belt sander ranges from 120 to 240. Start with a coarse grit for dull blades and finish with a finer grit for honing.

What Grit Belts For Knife Grinding?

For knife grinding, start with coarse belts (24–60 grit) for shaping. Use medium belts (80–120 grit) for refining the edge. Finish with fine belts (220–400 grit) for honing.

Conclusion

Crafting the perfect edge on a knife demands precision and the right tools. The belt sanders we’ve discussed stand out as top contenders. Whether you’re a budding blacksmith or seasoned artisan, selecting the ideal model is pivotal for honing your craft.

Embrace your passion for knife making with a quality belt sander that promises durability and flawless results.